DATA FLOW IN ORDER TO CASH

TECHNICAL DATA FLOW IN ORDER TO CASH

STEP 1:

Enter order received from customer in Order Management (Sales Order)

Also enter the line level information of items ordered for. On saving the information, the data will be inserted in OE_ORDER_HEADERS_ALL and OE_ORDER_LINES_ALL Order_number will be automatically generated, Header and line Flow_status_code = ‘ENTERED’

OE_ORDER_HEADERS_ALLEnter order received from customer in Order Management (Sales Order)

Also enter the line level information of items ordered for. On saving the information, the data will be inserted in OE_ORDER_HEADERS_ALL and OE_ORDER_LINES_ALL Order_number will be automatically generated, Header and line Flow_status_code = ‘ENTERED’

select header_id,

order_number,

request_date,

transactional_curr_code,

shipping_method_code,

ship_from_org_id,

ship_to_org_id,

org_id,

flow_status_code,

salesrep_id,

booked_date

from OE_ORDER_HEADERS_ALL

where flow_status_code = 'CLOSED'

and order_number = '56706'

OE_ORDER_LINES_ALL

select header_id,

line_id,

line_number,

ordered_item,

inventory_item_id ,

request_date,

promise_date,

schedule_ship_date,

pricing_quantity,

ordered_quantity,

cancelled_quantity,

shipped_quantity,

invoiced_quantity,

payment_term_id,

visible_demand_flag,

actual_shipment_date,

unit_selling_price,

tax_value,

cancelled_flag,

flow_status_code

from OE_ORDER_LINES_ALL

where header_id = 94256

STEP 2:

Book the order. Header Flow_status_code = ‘BOOKED’

Line Flow_status_code = ‘AWAITING SHIPPING’

The data is captured in WSH_DELIVERY_DETAILS.

WSH_DLIVERY_ASSIGNMENTS is the intermediate table between WSH_DELIVERY_DETAIL and WSH_NEW_DELIVERIES.

WSH_DELIVERY_DETAILS

select delivery_detail_id,

source_header_id,

source_line_id,

source_code,

customer_id,

inventory_item_id,

item_description,

ship_from_location_id,

ship_to_location_id,

move_order_line_id,

requested_quantity,

shipped_quantity,

subinventory,

released_status,

ship_method_code,

carrier_id,

net_weight,

unit_weight,

unit_volume,

unit_price,

inspection_flag,

source_header_number,

batch_id

from WSH_DELIVERY_DETAILS

where source_header_id = 94256

WSH_DELIVERY_ASSIGNMENTS

select delivery_detail_id ,

delivery_id,

parent_delivery_detail_id,

creation_date

from WSH_DELIVERY_ASSIGNMENTS

where delivery_detail_id in (216151, 216152, 216153) -- from above query

WSH_NEW_DELIVERIES

select delivery_id,

name,

status_code,

customer_id ,

gross_weight,

net_weight,

weight_uom_code,

confirm_date,

delivery_type,

source_header_id,

hash_string

from WSH_NEW_DELIVERIES

where delivery_id in (65881, 65882) -- from above query

STEP 3:

You can enter, view and update the Sales order information using Sales Order window.

Release the sales Order

Once the order is released, the data is updated in WSH_DELIVERY_DETAILS.The released_status becomes ‘Y’ and MOVE ORDER is generated in MTL_TXN_REQUEST_HEADERS and LINES. The move_order_line_id is also populated in WSH_DELIVERY_DETAILS

STEP 4:

Ship Confirm will update the data in WSH_DELIVERY_DETAILS. Released_status = ‘C’ and Shipped_quantity gets updated.

If you choose Tools >> Workflow Status then you will see that the workflow activity is in Deferred stage.

The concurrent program Workflow Background Engine needs to be executed to proceed further.

MTL_TXN_REQUEST_LINES

select line_id move_order_line_id,

header_id move_order_header_id,

line_number,

inventory_item_id,

organization_id,

quantity_delivered,

line_status,

txn_source_id,

transaction_type_id,

pick_slip_date

from MTL_TXN_REQUEST_LINES

where line_id in (174779, 174780, 174781)

MTL_TXN_REQUEST_HEADERS

select header_id move_order_header_id,

request_number move_order_number,

move_order_type,

organization_id,

header_status move_order_status

from MTL_TXN_REQUEST_HEADERS

where header_id in (55272, 55273)

MTL_MATERIAL_TRANSACTIONS

select transaction_id,

inventory_item_id,

organization_id,

subinventory_code,

transaction_type_id,

transaction_action_id,

transaction_quantity,

transaction_uom,

transaction_date,

distribution_account_id,

invoiced_flag,

shipment_number delvery_name

from MTL_MATERIAL_TRANSACTIONS

where shipment_number in ('65881', '65882')

Workflow Background Process executes Autoinvoice master, Autoinvoice Import Program.

The date is first transferred from Shipping to RA_INTERFACE_LINES_ALL.

Then the Autoinvoice Import program validates the records and populates the base table in Account Receivable. RA_CUSTOMER_TXN_ALL , RA_CUSTOMER_TXN_LINES_ALL

RA_CUSTOMER_TRX_ALL

select interface_header_attribute1,

customer_trx_id,

trx_number,

cust_trx_type_id,

complete_flag,

ship_date_actual

from RA_CUSTOMER_TRX_ALL

where interface_header_attribute1 = '56706'

Labels: O2C

friday, march 9, 2007

OM in Detail

Overview of Order Management in Order To Cash Process:

The following flowchart is self explanatory:

The following flowchart is self explanatory:

Oracle Order management supports multiple fulfillment models which are :

# For CTO, ATO, PTO

# Back To Back Orders

# Drop Ship to Customer

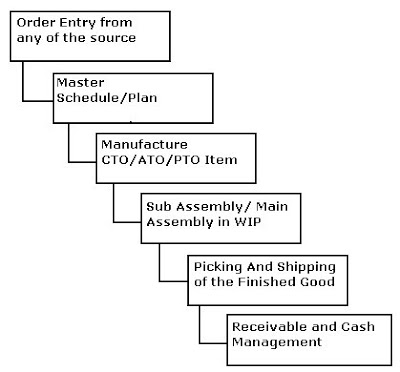

The flow for CTO, ATO, PTO would be as follows

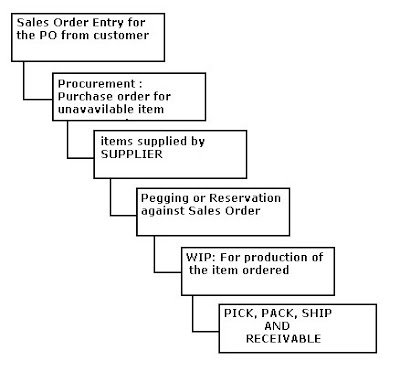

The flow for Back To Back Orders would be as follows

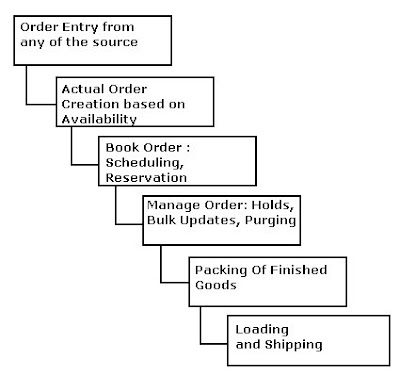

The flow for Drop Ship to Customer would be as follows

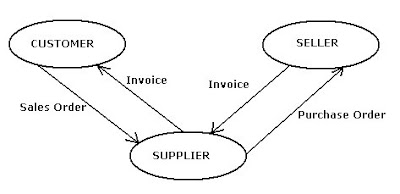

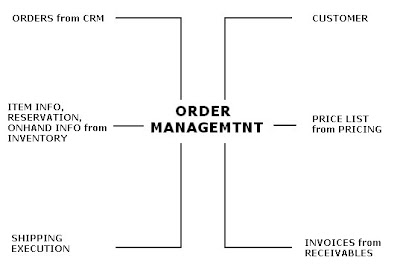

The integration of the diffrent modules is as follows:

Here you will come to know that which information is fetched from which module.

Please refer to following link from metalink which will give you the ERD [Entity Relationship Diagram] for the diffrent tables of modules. You need to have metalink access for this.

https://etrm.oracle.com/pls/trm11510/etrm_fndnav.show_object?n_appid=660&n_tabid=576&c_type=FILE

Labels: OM 1

thursday, march 8, 2007

ORDER TO CASH

Basic cycle in SCM will be O2C...

Lets have a look at this cycle flow then we will go in the processes in detail.

ORDER TO CASH CYCLE STEPS

-------------------------------

Lets have a look at this cycle flow then we will go in the processes in detail.

ORDER TO CASH CYCLE STEPS

-------------------------------

# Order placed by customer.

# Entered in Order Entry.

# Order fulfilled [manufactured/produced].

# Shipping execution.

# Order picked for release which generates the move order.

# This move order is for shifting the material ordered from subinv to staging area.

# Ordered product received by customer along with invoice.

# Auto invoice is the concurrent program which imports invoices, credit memos from other system to Oracle Applications. In receivable you can print the invoice and send it to customer.

# Payment done by customer.

# Receipt given.

# Entry to GL.

------------------------

ORDER LIFE CYCLE------------------------

1. ORDERING

2. SCHEDULE

3. SHIPPING

4. AUTOINVOICE TO RECEIVABLE

5. INVOICING

6. RECEIPTS

7. CASH MANAGEMENT

8. TRANSFER TO GL-----------------------

# Entered in Order Entry.

# Order fulfilled [manufactured/produced].

# Shipping execution.

# Order picked for release which generates the move order.

# This move order is for shifting the material ordered from subinv to staging area.

# Ordered product received by customer along with invoice.

# Auto invoice is the concurrent program which imports invoices, credit memos from other system to Oracle Applications. In receivable you can print the invoice and send it to customer.

# Payment done by customer.

# Receipt given.

# Entry to GL.

------------------------

ORDER LIFE CYCLE------------------------

1. ORDERING

2. SCHEDULE

3. SHIPPING

4. AUTOINVOICE TO RECEIVABLE

5. INVOICING

6. RECEIPTS

7. CASH MANAGEMENT

8. TRANSFER TO GL-----------------------

# ORDERINGorder placed by customer online/inventory replenishment/order entry manually by sales representative.

OE_ORDER_HEADERS_ALL

OE_ORDER_LINES_ALL

OE_ORDER_SOURCES

OE_TRANSACTION_TYPES_TL

# SCHEDULING

checking ATP, placing demand, and reserving on-hand Inventory, running pick release, and shipping the order.

MTL_ONHAND_QUANTITIES_DETAIL

MTL_TXN_REQUEST_HEADERS

MTL_TXN_REQUEST_LINES

# SHIPPING PROCESS

PICK RELEASE creates MOVE ORDER (request for movement of inventory from one location to staging area)

Detailing of MOVE ORDER (providing detail information about the inventory to be moved)

Transact the MOVE ORDER does the PICK CONFIRM. (items moved to staging area)

From staging the material is loaded to truck and shipped. Once loaded, you can run SHIP CONFIRM process. SHIP CONFIRM decrement inventory and update sales order.

# AUTO INVOICE

The Transaction data can be sourced from different legacy systems.

All the data is first laded in the interface table

RA_INTERFACE_LINES_ALL

RA_INTERFACE_SALESCREDITS_ALL :

RA_INTERFACE_DISTRIBUTIONS_ALL

Autoinvoice program when executed fetches the record from interface tables, validates the data and

correct records are pushed to base tables of AR.

# RECEIVABLE

Imported and manually entered Invoices are corrected and are printed.

Printed Invoice are sent to Customer.

Collect the payments from customer.

OE_ORDER_HEADERS_ALL

OE_ORDER_LINES_ALL

OE_ORDER_SOURCES

OE_TRANSACTION_TYPES_TL

# SCHEDULING

checking ATP, placing demand, and reserving on-hand Inventory, running pick release, and shipping the order.

MTL_ONHAND_QUANTITIES_DETAIL

MTL_TXN_REQUEST_HEADERS

MTL_TXN_REQUEST_LINES

# SHIPPING PROCESS

PICK RELEASE creates MOVE ORDER (request for movement of inventory from one location to staging area)

Detailing of MOVE ORDER (providing detail information about the inventory to be moved)

Transact the MOVE ORDER does the PICK CONFIRM. (items moved to staging area)

From staging the material is loaded to truck and shipped. Once loaded, you can run SHIP CONFIRM process. SHIP CONFIRM decrement inventory and update sales order.

# AUTO INVOICE

The Transaction data can be sourced from different legacy systems.

All the data is first laded in the interface table

RA_INTERFACE_LINES_ALL

RA_INTERFACE_SALESCREDITS_ALL :

RA_INTERFACE_DISTRIBUTIONS_ALL

Autoinvoice program when executed fetches the record from interface tables, validates the data and

correct records are pushed to base tables of AR.

# RECEIVABLE

Imported and manually entered Invoices are corrected and are printed.

Printed Invoice are sent to Customer.

Collect the payments from customer.